Oil/gas fired boiler series

Oil/gas fired boiler series

Waste heat boiler series

Waste heat boiler series

Biomass fired boiler series

Biomass fired boiler series

Coal fired boiler series

Coal fired boiler series

High voltage electrode boiler series

High voltage electrode boiler series

Series of steam generator for oil fields

Series of steam generator for oil fields

Energy saving and low nitrogen improvement project

Energy saving and low nitrogen improvement project

Low nitrogen improvement project for Shanghai Jinzhong square

With the continuous deepening of Shanghai's efforts to improve air quality and reduce PM2.5 concentration, the reduction of NOx in industrial boilers is also urgent. In this background, SIBRI established the "Combustion Technology Service Center", introduced the top international low nitrogen combustion technology, combined with our R & D capability, to serve domestic industrial boiler users. We expect to lead the low nitrogen combustion market in a standardized, scientific and orderly development. In January 2018, we successfully carried out the low nitrogen improvement work on a 5t/h boiler with German standard in Jinzhong Square. After testing, the full load emission is less than 50mg/m3.

Low nitrogen improvement project for Shanghai Lianhua Metal Products Co., Ltd.:

The company is equipped with two sets of oil fired boilers: WNS2-1.0-Y (Q) WNS4-1.0-Y (Q), with the brand of BRIGHT, horizontal steam boiler firing with 0# diesel oil. The boilers were inspected by Jiading Environmental Protection Dept. in 2016, the NOx emissions exceeded the requirement in the standard (150mg/m3 in the current "DB31/387-2014 boiler air pollutant emission standard").

According to the requirement of the company, we designed and prepared a set of advanced and scientific, safe and reliable, forward-looking and sustainable optimal improvement plan, to help the company completed the improvement work successfully, and meet the requirement of government environmental protection policy. The emission measured after improved is <40mg/m3.

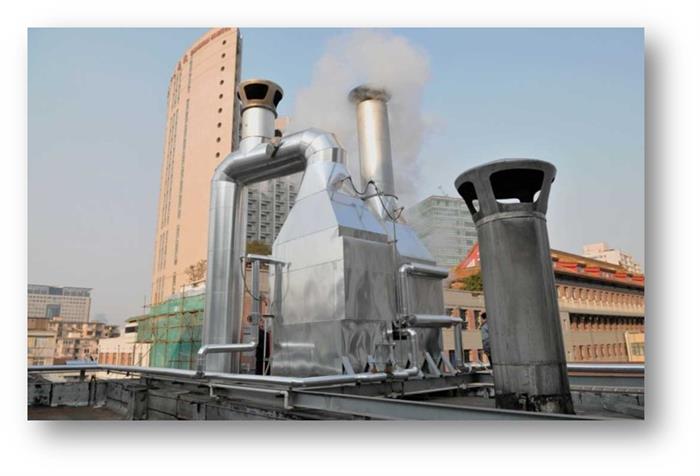

Energy saving improvement project from coal into gas in Shanghai Motor Factory Co. Ltd.:

The company has 3 sets of coal-fired boilers, including 1 set of 20t/h and 2 sets of 10t/h. According to Shanghai "12th Five-Year energy saving and emission reduction implementation plan” and “three year action plan of environmental protection and construction in Shanghai from 2012 to 2014”, the existing coal-fired boilers (clean energy (natural gas)) should be replaced by clean energy (natural gas). We designed and contracted the project.

The boiler house is composed of 3 sets of 4 t/h WNS steam boilers and related auxiliaries, and design real-time monitoring and remote transmission system of the boiler and auxiliaries operating conditions.

Condensing waste heat recovery unit on gas fired boilers in Zhongshan Hospital:

Use our patented technology to carry out the improvement of condensing waste heat recovery and utilization on 2 sets of 10t/h and 1 set of 6t/h gas fired boilers in Shanghai Zhongshan Hospital. The boiler flue gas temperature drops from 240℃ to 60℃, make the best use of sensible heat of flue gas and gasification latent heat of water vapor. After tested by Shanghai Energy Saving Supervision Center, the actual running energy-saving rate of the unit is up to 10%~15%.

Waste heat utilization of steam condensate in Pudong Holiday Inn:

Improve of the waste heat utilization in the hotel laundry and ironing room, use the steam waste heat after flat hot in the ironing equipment instead of the electric hot water boiler to heat the domestic water. The total cost of the project is 490 thousand Yuan. It has been operated safely for four years since completed the project improvement. Save electricity 1500kWh per day, and save the charges for electricity about 500,000 Yuan per year.

Study on the intensifying combustion and reburning device on a spreader-stoker-fired boiler:

In 2007, we jointly cooperated with the University of Shanghai for Science and Technology to carry out the research project of National Science and Technology Support Program "semi suspension back combustion type spreader-stoker-fired boiler and key technology”. Made the improvement on 10t/h spreader-stoker-fired boiler in Shanxi Chemical Plant (Datong Rubber Factory), to form new intensifying combustion and new reburning device, the thermal efficiency of the boiler is increased to 82% from 65%, the combustion efficiency is up to 92 ~ 96%, dust emission concentration is <100mg/Nm3, NOx emission concentration is <400mg/Nm3, smoke dust blackness drops to below level 1, energy-saving rate is 15% above. While increasing the combustion efficiency of the boiler, it also effectively solves the technical problems of high energy consumption and heavy pollution in industrial boilers.